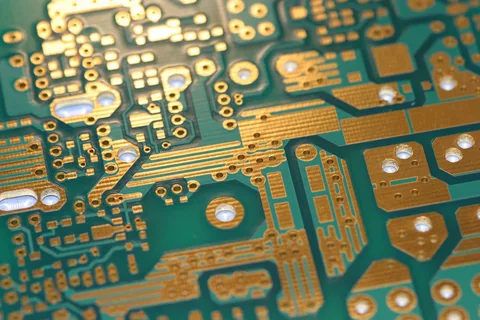

In the world of electronics, the Printed Circuit Board (PCB) is a foundational component that plays a critical role in how modern technology functions. From smartphones and computers to home appliances and industrial machines, PCBs are the unsung heroes behind the seamless operation of electronic devices. This article explores what printed circuit boards are, how they work, the different types, and why they’re so essential in today’s technology-driven world.

What is a Printed Circuit Board?

A Printed Circuit Board is a flat board made from non-conductive materials like fiberglass, which supports and connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs allow for the precise placement and interconnection of components such as resistors, capacitors, microchips, and diodes.

Unlike traditional wiring, PCBs offer a more compact, durable, and organized way to assemble electronic circuits. As technology has advanced, printed circuit boards have become more complex, supporting multi-layered designs that can handle increasingly sophisticated electronic functions.

History of Printed Circuit Boards

The concept of the printed circuit board dates back to the early 20th century. In 1936, Austrian engineer Paul Eisler is credited with inventing the first true PCB while working on a radio set. During World War II, PCBs began to be used in military applications, and by the 1950s and 1960s, they became more common in consumer electronics.

Over the decades, the printed circuit board has evolved significantly, with modern PCBs supporting miniaturization, high-speed processing, and mass production at a reduced cost.

Types of Printed Circuit Boards

There are several types of printed circuit boards, each designed for specific applications:

- Single-Sided PCBs: These are the simplest type, with components mounted on one side and conductive copper tracks on the other. They are cost-effective and used in low-density applications like calculators and simple electronics.

- Double-Sided PCBs: These boards have conductive layers on both sides, allowing for more complex circuits. Components can be mounted on both sides, and through-hole technology is often used to connect the layers.

- Multi-Layer PCBs: These consist of three or more layers of conductive material separated by insulating layers. They are commonly used in complex devices like computers, medical equipment, and high-speed servers.

- Rigid, Flexible, and Rigid-Flex PCBs: Rigid PCBs are solid and inflexible, while flexible PCBs can bend and twist, making them ideal for compact devices. Rigid-flex PCBs combine both features, offering versatility in high-performance applications.

How Printed Circuit Boards are Manufactured

The manufacturing process of a printed circuit board involves several steps:

- Designing the Layout: Using CAD software, engineers design the PCB layout based on circuit requirements.

- Printing the Design: The layout is printed onto the board using a photolithographic process.

- Etching: Excess copper is etched away to leave behind the desired circuitry.

- Drilling: Holes are drilled for component leads and vias (vertical interconnect accesses).

- Plating and Solder Mask Application: Copper is plated onto the drilled holes, and a solder mask is applied to prevent solder bridging.

- Silkscreen Printing: Labels, logos, and component identifiers are printed.

- Assembly and Testing: Components are mounted, and the board is tested for functionality.

Applications of Printed Circuit Boards

Printed circuit boards are integral to almost every electronic device. Their applications span across:

- Consumer Electronics: Smartphones, tablets, laptops, televisions, and gaming consoles.

- Medical Devices: Pacemakers, imaging systems, and diagnostic machines.

- Automotive Industry: Control systems, navigation, and infotainment units.

- Industrial Equipment: Automation tools, sensors, and power supplies.

- Aerospace and Defense: Communication equipment, navigation systems, and radar.

Advantages of Using Printed Circuit Boards

- Compact Design: PCBs allow for high component density, leading to smaller device sizes.

- Reliability: Fixed connections reduce the chances of loose wires and short circuits.

- Ease of Maintenance: Clearly labeled components and paths simplify troubleshooting and repair.

- Mass Production Friendly: PCBs are easy to replicate with high precision, reducing production costs.

Conclusion

The printed circuit board is a vital component that underpins nearly all modern electronic devices. As technology continues to evolve, PCBs will only become more advanced, enabling faster, more efficient, and compact electronic systems. Whether you’re an engineer, a hobbyist, or simply curious about how electronics work, understanding the importance of PCBs is essential in appreciating the inner workings of the devices we use every day.